It’s been an interesting spring and summer for Folsom Custom Skis. After a record breaking 2019-20 season, our momentum was immediately halted by the COVID-19 Pandemic, along with thousands of other small businesses. When the ski resorts shut down we began lightly marketing our touring skis and construction types, but recognized that skiing in the backcountry realistically put our healthcare systems under even more pressure. It was not the time for that.

The pandemic continued to grow, and we knew we needed to put our machinery to work to assist in PPE manufacturing. At the same time, we knew we had to continue innovating our shape offerings, and scale our shop to facilitate great ski production capabilities. As you could guess, this made for our busiest summer to date, all in the name of innovating, adapting, and assisting.

Starting in April, we began manufacturing PPE face shields for frontline healthcare workers. There was initially a massive supply gap in Colorado for face shields, but thanks to American manufacturers, this gap quickly shrank. Face shields were purchased by hospitals and other primary care providers, as well as on a donation basis from generous Folsom customers.

As local businesses began to re-open, Folsom found a more technical application of the shop machinery in manufacturing PPE cashier’s shields / partitions. After building an installation for our favorite café down the street from Folsom’s Denver HQ, we built set sizes of these cashier’s shields, and found ourselves selling to restaurants, retail stores, primary healthcare facilities, and numerous other office types.

Larger custom installations have included Regis University, Rocky Mountain Primary Care, and all of evo’s US brick-and-mortar stores.

While custom ski manufacturing is back to an all-time high, we are still manufacturing PPE as needed in order to keep businesses (their employees and customers alike) safe.

The most exciting addition to the Folsom lineup is the all new Spar Turbo. Joining the award-winning Spar family is a mid-width super-carver that can handle the entire mountain.

“The Spar Turbo completes the Spar Family in the form of a truly badass carving ski” says Folsom Chief of Operations Max Tabor. “The ski perfectly executes mega-short turns but is wide enough to track through mixed snow conditions and even deeper snow with grace and style.”

You can read more or order a pair of Spar Turbos of your own via the product page here.

Also joining the 2021 lineup are added lengths for Folsom’s new best selling ski, the Primary 104, now available in a length span of 161 to 191cm. The new shorter length carries with it a snappy 17m radius on a 102mm underfoot platform.

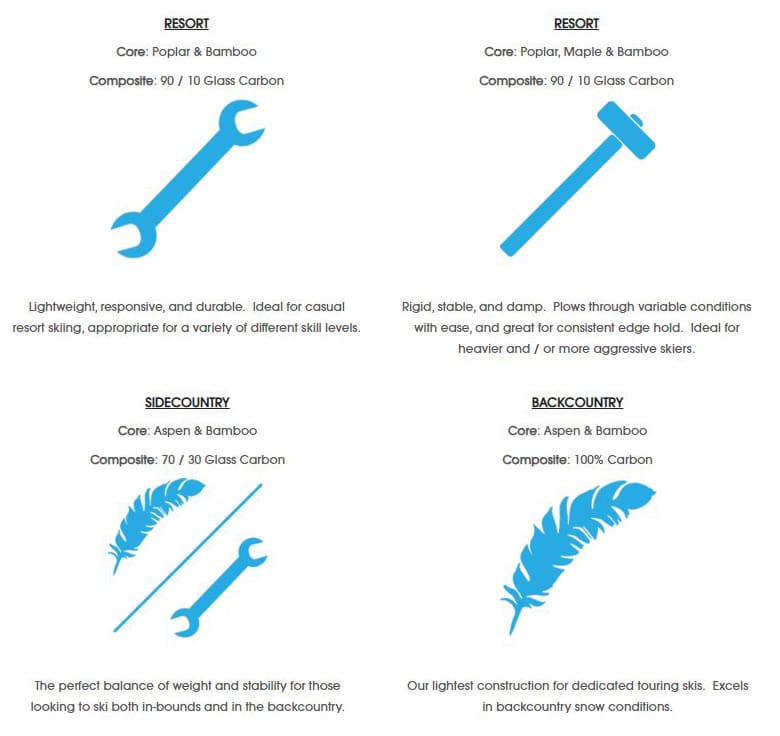

We know that custom ski design can be intricate, and that’s why we’re here to help, but in an effort to educate our audience on the materials used and design choices made in our custom fit consultations, we’ve outlined some of our go-to construction types that align frequently with customer’s skiing preferences. Of course we are still happy to open the conversation up to the full offering of Folsom custom build options, but these are a few of our favorites:

With the 2020-21 resort policies still very much up in the air, we’ve taken it upon ourselves to market Folsom’s lightweight touring construction more than ever. Now all of your favorite shapes can be built in Folsom’s signature touring construction, which incorporates a lightweight Aspen & Bamboo core blend (available in 3 flex index options), full carbon fiber laminate, and unique touring tail to give you seamless skin attachment in a slender package.

Also available with touring skis are a full suite of touring bindings from Marker (Alpinist, Kingpin, and Duke PT) as well as custom Folsom skins, all of which are available at a discounted price exclusive to Folsom customers.

On top of all of this, Folsom’s private Denver, CO manufacturing facility has undergone a massive retooling project over the warmer months, most notably in the form of converting all 3 of our ski presses from single ski pressing capability to dual bay setups. Through this conversion, the time it takes to press 1 pair of skis has been nearly cut in half, which adds a huge efficiency factor to Folsom’s ski production.

Additionally, we are in the process of expanding our Denver shop to take on another 1000 square feet of mixed production / office space at Folsom HQ. Simply put, this will give us more space to build more skis, additional office space for in-person custom fit consultations, and more robust inventory space to get you your Folsom products as quickly and efficiently as possible. This topic and much more are covered in our latest GEAR:30 podcast with BLISTER’s Jonathan Ellsworth and Folsom’s Mike McCabe.

Just around the corner starting in early November will be the return of our Aspen Showroom and Sales Office, based again at Aspen’s premier bike shop, The Hub of Aspen (616 E Hyman Ave). The shop will be open daily (exact hours TBD) complete with a full fleet of demos (both alpine and touring skis), prebuilt signature series shapes for purchase, and custom fit specialists to bring your dream skis to life in person, all in the heart of our favorite ski town.

We know that it’s been a strange year, and we also know that there are changes to the ski industry on the horizon that we may have never imagined. But no matter what the circumstances, Folsom is still committed to world class ski building, and continued innovation, both inside and outside of our shop walls. We will continue to use our machinery to help prevent the spread of COVID-19 and protect businesses as we navigate these trying times safely and responsibly.

Fear not, Folsom Custom Skis isn’t going anywhere. We will weather this storm together, and this season are more committed than ever to innovating, adapting, and assisting.