If you have ever been curious about how skis are made, you have probably learned that not all skis are made equal. Nearly every ski you can find on the market seems to made of exotic cores, state of the art composites, and base material that can withstand the harshest impacts. To the naked eye, one ski just looks like every other ski. However, there are important distinctions that need to be made in order to understand why one ski feels different from another. One element of ski design that is often overlooked by the consumers, is sidewall configuration as part of a ski’s construction.

Sidewalls on skis are strips of dense plastic that are incorporated to the outside of the ski core, underneath the topsheet, and above the edges of the base. By being located where they are, they prevent any damage from the outside from coming in contact with the core of the ski so that the overall integrity of the skis are kept intact. This means that when you’re on the chairlift using one ski to scrape off the snow from the other ski, if you miss, all you’ll be hitting is the plastic sidewall rather than the wood core. Similarly, if you drop your skis or hit a small rock from the side, the core is undamaged as the sidewall will take the impact.

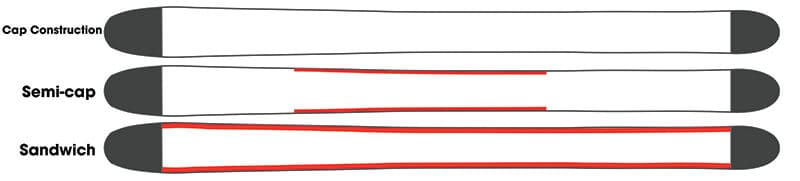

There are 3 main sidewall construction types that skis use: sandwich, semi-cap and cap construction. The biggest thing to remember here, is that they are all different variations of how much sidewall is being used. The sidewalls of skis are very important because they determine how torsionally rigid a ski is. Without getting too fancy with our terminology, torsional rigidity is defined as a skis willingness to twist and bend from edge to edge. Having a ski with high torsional rigidity is very important when getting up on an edge, because it means that the edges will be consistent and rigid, rather than deflecting off the snow and not engaging the edge as you’d like it to. Because sidewall material is very dense it offers high torsional rigidity where it’s located right over the edges of the ski. An additional benefit of sidewalls over the edges is that it makes the skis much more durable because it makes skis less prone to edge compression. When landing on a hard object like a rock (hopefully by accident) that rock will force itself into the ski. Because sidewalls are made of dense plastic, as that rock forces the edge of the ski upward, the strength of the sidewall prevent it from bending too far and compressing more than it should.

This makes for easier repair, and because the sidewall took most of the impact force, the core of the ski is much more likely to be intact. The downside of sidewalls being so dense is that they add weight to a ski, and some manufacturers want to prioritize weight over performance (specifically torsional rigidity) and durability in their skis…

Each of the three types of sidewall constructions are centered around how much sidewall is being used, and where along the length of the ski that sidewall is placed. Sidewalls are always placed outside the side of the core, underneath the top sheet, and above the edges and base material of a ski. In the graphic below, the red symbolizes the placement of sidewall material in our three different sidewall construction types. Sandwich construction uses sidewalls along the entire length of the ski, semi-cap construction uses shorter sidewalls spanning only the center of the ski, and capped construction uses no sidewall at all. We’re going to break down the three types of ski construction to explain what the benefits and disadvantages of each are.

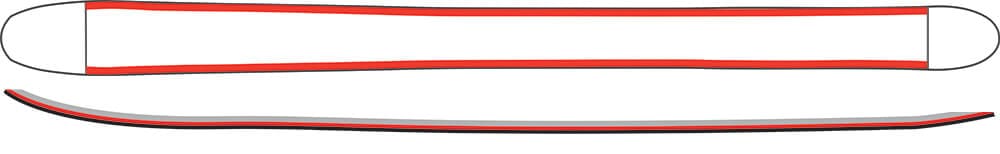

Skis with sandwich construction have the highest torsional rigidity and durability that you can find. Because they use the most sidewall, that means that every part around the edge will be sturdy, and not allow the ski to twist too much from edge to edge. This construction style works very well for all types of skis because it offers the best, most consistent feel to a ski, and you’ll be able to trust that your edges will grip the snow in tougher conditions. Another advantage to sandwich construction skis is that because the sidewalls sit right over the edges of the ski, if you were to hit a rock or damage the edge of the ski, typically no damage is done to the core, only the sidewall. This is much easier to repair because it’s simple to replace an edge, move the sidewall back into place, and patch the base. Attempting to fix a broken ski core is futile and the repair will frequently not hold. Overall, skis made with full sidewalls are more consistent with their edge hold thanks to their high torsional rigidity, and overall sturdier skis with longer lifetimes.

Skis with sandwich construction have the highest torsional rigidity and durability that you can find. Because they use the most sidewall, that means that every part around the edge will be sturdy, and not allow the ski to twist too much from edge to edge. This construction style works very well for all types of skis because it offers the best, most consistent feel to a ski, and you’ll be able to trust that your edges will grip the snow in tougher conditions. Another advantage to sandwich construction skis is that because the sidewalls sit right over the edges of the ski, if you were to hit a rock or damage the edge of the ski, typically no damage is done to the core, only the sidewall. This is much easier to repair because it’s simple to replace an edge, move the sidewall back into place, and patch the base. Attempting to fix a broken ski core is futile and the repair will frequently not hold. Overall, skis made with full sidewalls are more consistent with their edge hold thanks to their high torsional rigidity, and overall sturdier skis with longer lifetimes.

The downside to sandwich construction is that sidewalls are relatively heavy because of how dense they are. So if performance and durability is less of a priority than weight is, you may not want a ski with full sidewall, sandwich construction.

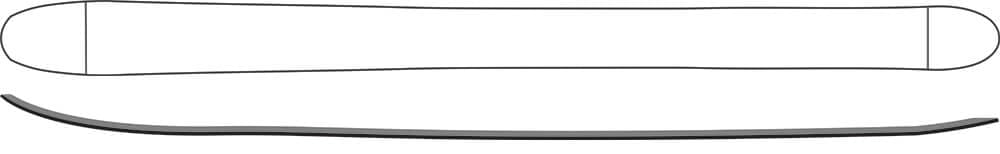

While sandwich construction utilized sidewalls around the entire outside of the ski, cap construction skis use none at all. To hold the sides of the ski together, cap constructed skis have the topsheet material fold over the top of the core material and around the sides of the core where the sidewall would sit on a sandwich ski, creating a rounded appearance. The benefits of cap construction, because they don’t use any sidewalls at all, mean that they are the lightest of the three construction styles. Because they’re lighter, these kinds of skis are typically meant to be used for dedicated touring and long ascents.

While sandwich construction utilized sidewalls around the entire outside of the ski, cap construction skis use none at all. To hold the sides of the ski together, cap constructed skis have the topsheet material fold over the top of the core material and around the sides of the core where the sidewall would sit on a sandwich ski, creating a rounded appearance. The benefits of cap construction, because they don’t use any sidewalls at all, mean that they are the lightest of the three construction styles. Because they’re lighter, these kinds of skis are typically meant to be used for dedicated touring and long ascents.

However, in line with the torsional rigidity aspect that sidewalls provide, cap construction skis are typically not the most reliable when it comes to edge hold. These skis can feel very flimsy and will bounce off the snow under force (rather than grip the snow and stay stable). This style used to be very popular in the ski industry, but because sidewall material prices have decreased and companies have wanted to make better products, the vast majority of other company’s ski lineups will not have any cap construction skis at all.

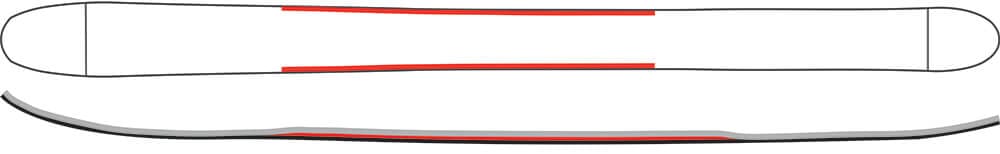

As the name would imply, semi-cap construction is a bit of a hybrid option, using areas of sidewall, and areas of cap construction. Semi-cap construction utilizes much shorter pieces of sidewall that are placed directly in the center of the ski (where skis often take the most impact and receive the most energy input from the user). After the short sidewall section underfoot, semi-cap constructed skis then eliminate the sidewall and wrap the topsheet over the core (cap construction) for the remainder of the tip and tail of the ski. Overall, this gives the skis an area of torsional rigidity and strength underfoot, but saves some weight by not utilizing sidewalls for about half of the skis running length.

As the name would imply, semi-cap construction is a bit of a hybrid option, using areas of sidewall, and areas of cap construction. Semi-cap construction utilizes much shorter pieces of sidewall that are placed directly in the center of the ski (where skis often take the most impact and receive the most energy input from the user). After the short sidewall section underfoot, semi-cap constructed skis then eliminate the sidewall and wrap the topsheet over the core (cap construction) for the remainder of the tip and tail of the ski. Overall, this gives the skis an area of torsional rigidity and strength underfoot, but saves some weight by not utilizing sidewalls for about half of the skis running length.

The unfortunate aspect to semi-cap construction is that by missing the sidewalls near the upper portions of the ski, it is still difficult to fully use the edges of the ski to drive a turn, particularly for advanced to expert level skiers. Just like how a cap construction ski’s edge may bounce around and twist from edge to edge while skiing, a semi-cap ski will do the same, just in less area. Specifically, when you’re in a turn and suddenly want to make a sharper turn, semi-cap skis would much rather wash out of the turn than engage the upper tip portion of the edge to cleanly tighten the turn.

You may now be thinking, “ok, I have all this newfound knowledge of ski construction, but which is best for me?” The essential trade-off with each construction style is weight versus performance (a subject that keeps us up at night on a regular basis). Here at Folsom, we only make sandwich constructed skis because we believe in prioritizing torsional rigidity, consistent edge hold, and durability on our skis. We know that we can pull weight out of a ski in other areas that are less compromising to that ski’s performance (primarily core and composite layup) but would prefer to keep the sidewalls to give us the most bombproof skis on the on market. If you need a sub-1000 gram pair of ski mountaineering, then Folsom may not be the brand for you. But we are more more than willing to discuss what weight goals you may need for your skis, all while offering the suite of benefits that sandwich construction skis offer. Fill out a Custom Fit Form today to get started creating your perfect pair of full sidewall skis today.